flow rate calculator 3d printer

Remember the width of the track is usually the same as the nozzle diameter although it is often better to print a wider track if you want improved mechanical performance eg. Consequentially dimensional accuracy and line widths all go out of the window as there is no benchmark to calculate from.

Section 1 8 Esteps And Flow Rate Youtube

Calculate the maximum flow rate.

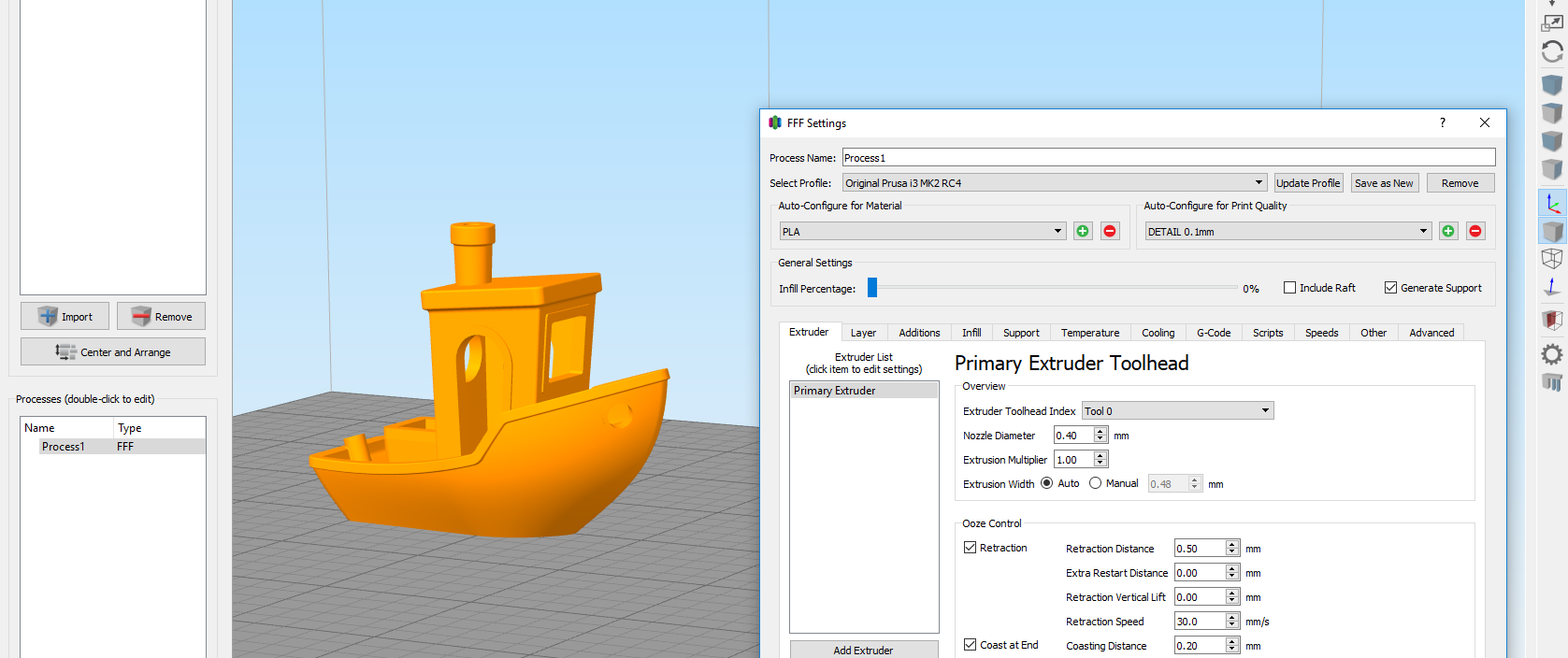

. To use this calculator print a 20mm x 20mm x 20mm cube in vase mode and then measure the top 5 layers with your caliper. A volcano-type is closer to 20-30 mm 3 s whilst E3D claim 110 mm 3 s for their super volcano. The Maximum volumetric speed setting MVS in PrusaSlicer is one of the most powerful features of this slicer yet it is poorly documented and not well understood.

A volcano-type is closer to 20-30mm 3 s whilst E3D claim 110mm 3 s for their super volcano. This is typical for most printers as purchased. Naturally for many instances this is either too much or on the odd occasion too little.

The flow rate also known as extrusion multiplier is a slicer setting that determines the amount of plastic a 3D printer will extrude. With 100 flow rate the cube is oversized. Divide the maximum flow rate obtained in step 6 by the surface area of your normal print line obtained in step 7.

The flow rate compensation factor is a percentage value that the printer multiplies with its current flow rate to calculate the effective flow rate it will use for the printing process. Using these settings the 3D printer figures out how fast to run the extruder motors to send enough filament for printing through the hotend. The formula is.

Thus the need for calibrating the filament flow rate. Maximum volumetric speed in PrusaSlicer. Lets assume that we have a maximum flow rate of 1386 mm³ and we want to print with a layer height of 02 mm and a layer width of 048 mm.

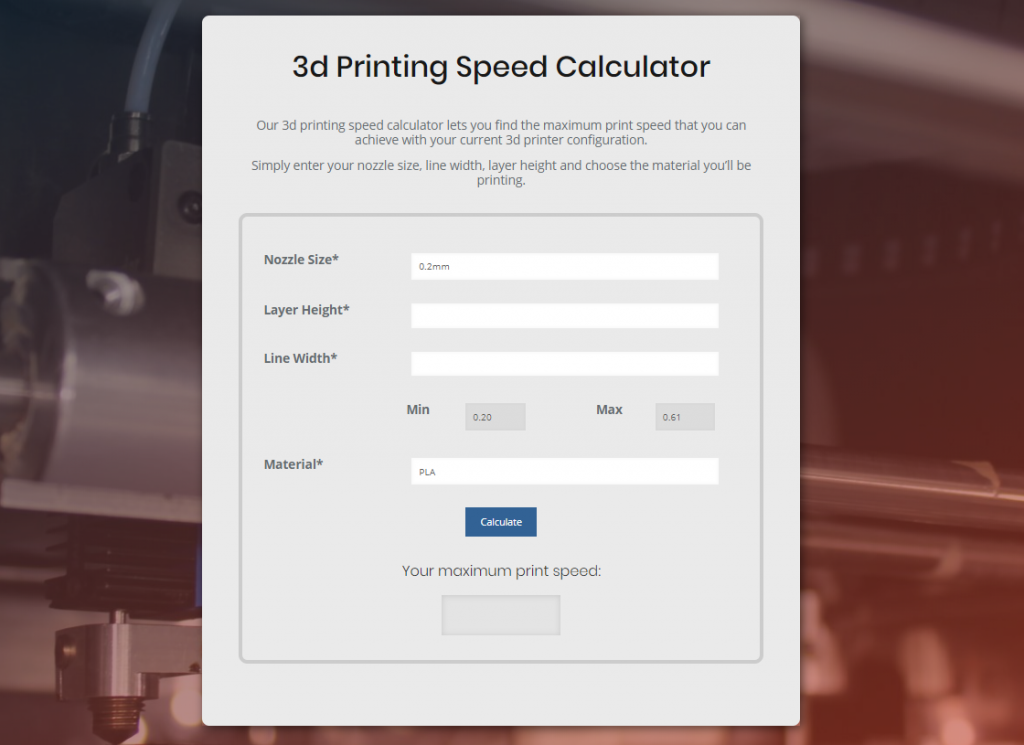

04mm nozzle 048mm line width layer height. The word ovoid emerged in the. Use this calculator correct for the expansion of the filament by adjusting the flow rate.

Now we can use this. Max flow rate 10 pi 1715 2 2 10 314 175 2 175 2 2405 mm³ s. Max flow rate 10 pi 1715 2 2 10 314 175 2 175 2 2405 mm³ s.

How to calibrate the 3d printer before an extruder change Learn what it is and how it can help fix print issues. Enter the values below to see how you can adjust your flow compensation to produce the properly sized line width of. If we know the maximum flow rate of the hot end we can use this formula.

How To Calibrate 3D Printer Flow Rate. This value is a safe max printing speed for your 3D printer with the nozzle diameter temperature and filament you previously set. FR Nozzle size mm x layer height mm x print speed mms mm3s.

Flow rate calibration is extremely simple and can be completed in less than 30 minutes using the process below. Flow rate calculator 3d printer. Extrussions speed is F600 then divide the 600 by 60 to get the speed mm this would be 10 mm second here.

Flow rate is a multiplier denoted in percentages that determines the amount of plastic the printer extrudes at any given moment. 3d Printing Speed Calculator Our 3d printing speed calculator lets you find the maximum print speed that you can achieve with your current 3d printer configuration. Affordable functional prototypes production parts in more than 70 metals and plastics.

On the other hand the feed rate is a multiplier denoted in percentages the printer uses to calculate the movement speed for all axes including the E axis. To correct this deviation we will. Lets assume that the max.

The printing parameters are. Nozzle of 040 mm width of layer 080 mm to create two outer layers and make the measurement more accurate and flow rate of 100. π a2 b2.

Calibrating the flow rate will involve printing a test cube and measuring its walls to identify the actual flow rate compared to the flow rate value. Measure near the center of the cube not near the edges. The MVS setting essentially imposes a governor on the maximum amount of filament that the slicer will attempt to push through your 3D printers.

Use this calculator correct for the expansion of the filament by adjusting the flow rate. The default value for the flow rate is usually 100. As you can see despite sounding similar flow rate and.

Ad From prototype to production get quality parts at consistently low prices. When using PLA with 100 flow rate recommended 90 we have obtained a measurement of 088 mm clearly oversized. Rotation_distance.

You can calculate the flow rate in five simple steps. Hence by default 3D printing slicers set the flow rate to 10 or 100. With a 04mm nozzle and a flow rate of 1 or 100 the thickness of a single wall should be 04mm.

Recommended maximum speed maximum flow rate layer height extrusion width to calculate the maximum printing speed. Printing a 06mm track from a 04mm nozzle.

Calibrating Filament Flow Rate To Improve 3d Print Quality Make N Print

Resistor Series And Parallel Calculator Resistor Time Constant Ohms Law

3d Print Speed How To Find The Optimal Speed For Reliable And Constant Print Quality

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner

Online Calculator For Metal 3d Printing 2021 03 12 Industrial Heating

Calibrating Filament Flow Rate To Improve 3d Print Quality Make N Print

How To Calibrate Your Extruder E Steps Flow Rate Perfectly 3d Printerly

Hexapod Robot Based On Fpga Robot Robotics Engineering Arduino

Flow Rate Calibration Improve Print Accuracy 3d Print Beginner

Mortgage Refinance Mortgagelawyer Mortgage Refinance Mortgagetools Mortgage Refinance Mortgage Mortgage Refinance Calculator Home Equity Loan Calculator

Calibrating Filament Flow Rate To Improve 3d Print Quality Make N Print

Rental Property Roi And Cap Rate Calculator And Comparison Etsy Canada Rental Property Rental Property Management Income Property

3d Print Speed How To Find The Optimal Speed For Reliable And Constant Print Quality